A yau, bari mu fahimci abin da ke haifar da etching factor a cikin yumbura.

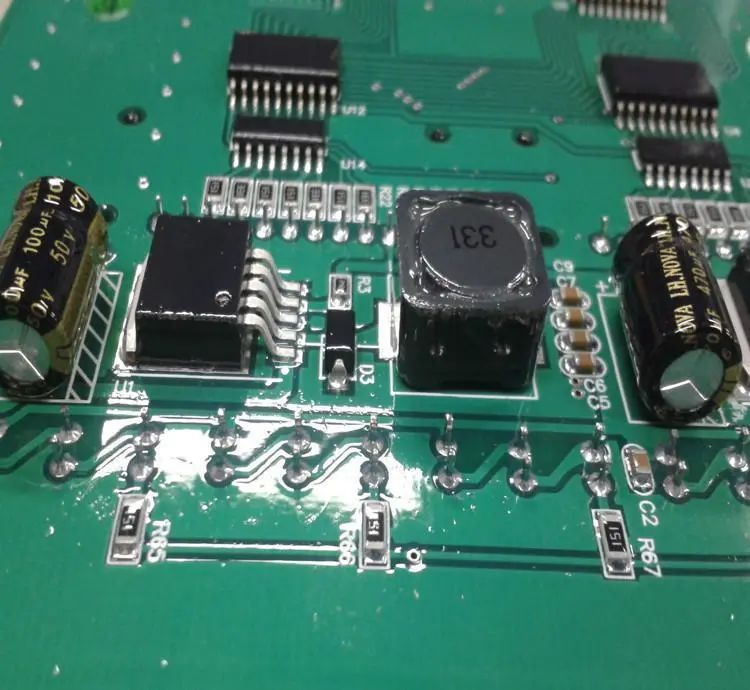

A cikin PCB yumbu, akwai nau'in PCB da ake kira DBC ceramic PCB, wanda ke nufin abubuwan da aka haɗa da yumbura kai tsaye. Wannan sabon nau'in kayan haɗin gwiwa ne inda yumbu mai yumbu da aka yi da aluminum oxide mai ƙoshin ƙoshin lafiya ko aluminium nitride yana haɗe kai tsaye da ƙarfe tagulla. Ta hanyar dumama zafi mai zafi a 1065 ~ 1085 ° C, ƙarfe na jan ƙarfe yana oxidizes kuma yana yaduwa a yanayin zafi mai zafi tare da yumbu don samar da narke mai eutectic, haɗa jan ƙarfe zuwa yumbu mai yumbu da kuma samar da yumbu mai hade da ƙarfe.

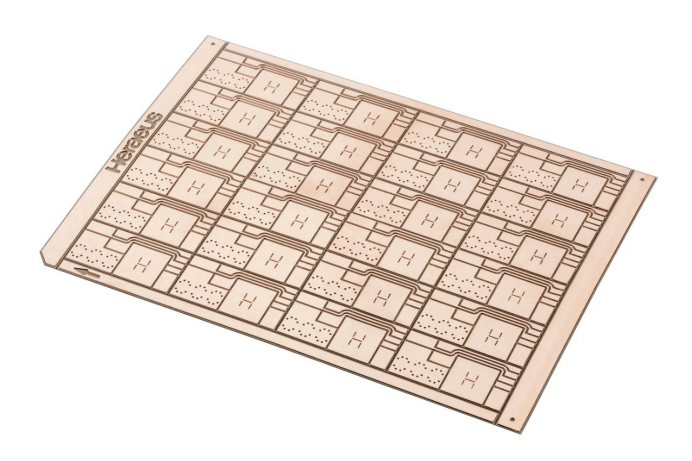

Tsarin tsari don DBC yumbura PCB shine kamar haka:

- Tsaftace kayan danye

- Oxidation

- Sintering

- Gabatarwar magani

- Aikace-aikacen fim

- Bayyanawa (Hotuna)

- Ci gaba

- Etching (lalata)

- Bayan jiyya

- Yanke

- Dubawa

- Marufi

Don haka, menene dalilin etching?

Etching wani tsari ne na yau da kullun wanda ke kawar da duk wani yadudduka na tagulla akan yumbura gaba ɗaya ban da Layer na anti-etch, don haka yana samar da da'ira mai aiki.

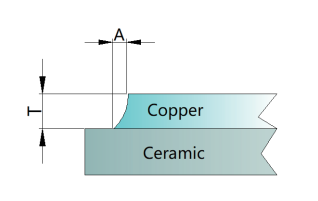

Hanyar yau da kullun tana amfani da etching sinadarai. Duk da haka, yayin aikin etching tare da maganin etching na sinadarai, ba wai kawai foil ɗin tagulla ya ƙulla a tsaye ba, amma kuma an yi shi a kwance. A halin yanzu, etching ta gefe a cikin hanyar kwance ba makawa. Akwai ma'anoni daban-daban guda biyu don ma'anar etching F, wasu mutane suna ɗaukar ƙimar zurfin T zuwa faɗin gefe A, wasu kuma suna ɗaukar wata hanya. Wannan labarin yana ƙayyadaddun: rabo daga zurfin T zuwa faɗin gefe A ana kiransa etching factor F, wato F=T/A.

Gabaɗaya, masu kera yumbura na DBC suna buƙatar ma'aunin etching F>2.

A cikin labarin na gaba, za mu mai da hankali kan tasirin canje-canje a cikin abubuwan da ke haifar da etching yayin kera PCB yumbura.

Hausa

Hausa English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba