Yau, za mu gabatar da wani ɓangare na sharuɗɗan PCB SMT Stencil .

Sharuɗɗa da ma'anar da muka gabatar da farko suna bin IPC-T-50. An samo ma'anar ma'anar da alamar alama (*) daga IPC-T-50.

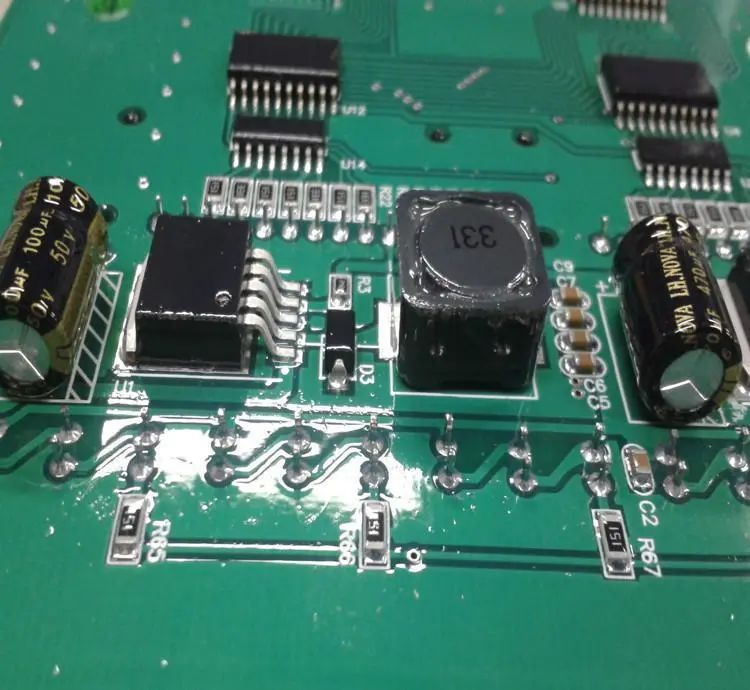

1. Budewa: Buɗewa a cikin takardar stencil ta inda Ana ajiye man siyar a kan kwamfutocin PCB.

2.

3. Iyaka: polymer ko bakin karfe da aka shimfiɗa a kusa da gefen takardar stencil, yin hidima don kiyaye takardar a cikin wani yanayi mai laushi da taut. Ramin yana kwance tsakanin takardar stencil da firam, yana haɗa su biyun.

4. Solder Manna Rufe Shugaban Buga: Shugaban firintar stencil wanda yana riƙe, a cikin sassa guda ɗaya wanda za'a iya maye gurbinsa, ƙwanƙolin squeegee da ɗakin matsi mai cike da manna solder.

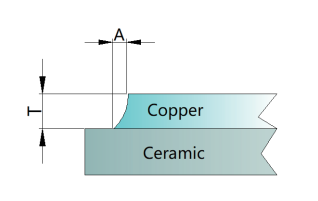

5. Factor Factor: Ma'anar etch shine rabon etch zurfin zuwa na gefe etch tsawon lokacin da etching tsari.

6.

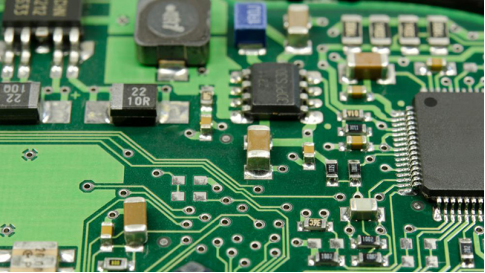

7. Kunshin Sikeli mai Kyau BGA/Chip (CSP) : BGA (Ball Grid Array) tare da filin wasan ƙwallon ƙasa da ƙasa da 1 mm [39 mil], wanda kuma aka sani da CSP (Package Scale Package) lokacin da yankin fakitin BGA / yankin guntu bare shine ≤1.2.

8. Fasahar Fine-Pitch (FPT)*: Dutsen saman saman fasaha inda nisan tsakiya-zuwa-tsakiyar tsakanin tashoshi masu siyar da abubuwa shine ≤0.625 mm [24.61 mil].

9. Foils: Siraran zanen gado da ake amfani da su wajen kera stencils. .

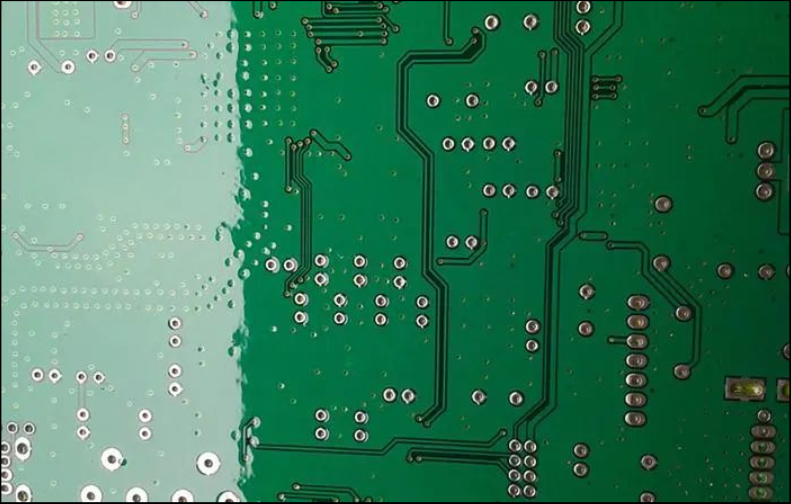

10. Frame: Na'urar da ke riƙe da stencil a wurin. Firam ɗin na iya zama rami ko kuma an yi shi da simintin aluminium, kuma stencil ɗin ana kiyaye shi ta hanyar manne raga zuwa firam ɗin dindindin. Wasu stencil za a iya daidaita su kai tsaye a cikin firam ɗin tare da ƙarfin tashin hankali, waɗanda ke nuna rashin buƙatar raga ko madaidaicin madaidaicin don amintaccen stencil da firam.

Hausa

Hausa English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba