A yau, za mu koyi game da manyan kayan da aka yi su cikin SMT Stencil.

SMT stencil da farko ya ƙunshi sassa huɗu: firam, raga, stencil foil, da m (viscose). Mu yi nazarin aikin kowane bangare daya bayan daya.

1. Frame

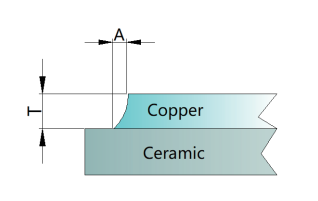

Za'a iya raba Frames zuwa nau'ikan cirewa da tsayayyen nau'ikan. Firam ɗin da za a iya cirewa kai tsaye suna hawa takardar ƙarfe a kan firam ɗin, suna ba da damar yin amfani da firam guda ɗaya. Kafaffen firam ɗin suna amfani da manne don haɗa raga zuwa firam ɗin, wanda daga nan kuma ana ƙara samun tsaro da manne. Kafaffen firam ɗin suna da yuwuwar cimma daidaiton takaddar takarda na karfe, yawanci jere daga 35 zuwa 48 N/cm². (Hanyoyin da aka yarda don daidaitaccen firam ɗin ƙayyadaddun firam shine 35 zuwa 42 Newtons.)

An ƙaddara girman firam ɗin ta buƙatun buƙatun na'urar buga fa'idar solder, tare da misalai kamar firinta na DEK 265 da samfurin firinta na MPM UP3000, waɗanda ke amfani da girman firam na 29" x 29" (735 x 735 MM) da aka yi da aluminum gami, tare da ƙayyadaddun bayanin martaba na 1.5" x 1.5". Don firintocin manna mai siyar da ta atomatik, girman firam ɗin yana kusan 22" x 26" (560 x 650 mm). Samfurin asali: (CM) 20*30, 30*40, 37*47, 42*52, 50*60, 55*65, 23"*23", 29"*29". Kauri na gama gari: (MM) 0.05 (ba a cika amfani da shi ba), 0.08 (ba a cika amfani da shi ba), 0.10, 0.12, 0.13, 0.15, 0.18, 0.20, da sauransu.

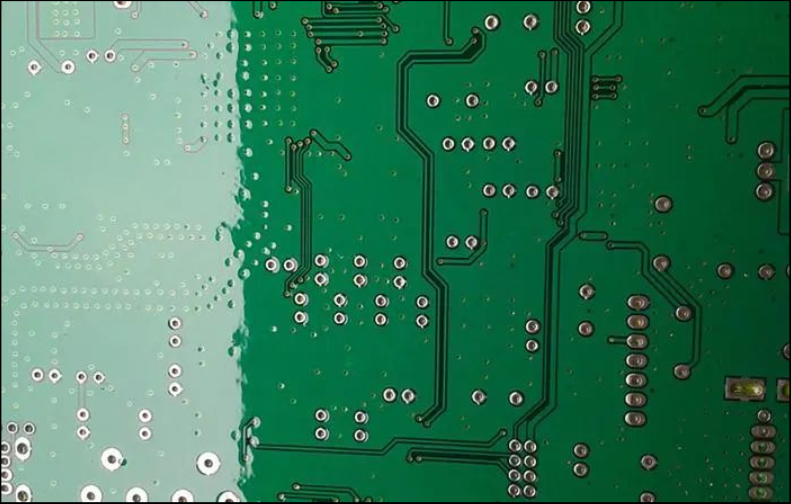

2. Sarka

Ana amfani da raga don amintaccen takardar karfe da firam kuma ana iya raba shi zuwa ragar bakin karfe da ragamar polyester mai girma. Ragon waya na bakin karfe yawanci yana amfani da raga kusan 100, yana samar da tsayayye kuma isasshe tashin hankali, amma yana iya lalacewa kuma yana rasa tashin hankali akan tsawaita amfani. Rukunin polyester, wanda aka yi da kayan halitta, shima yana amfani da raga guda 100 kuma yana da ƙarancin lalacewa, yana ba da tsawon sabis.

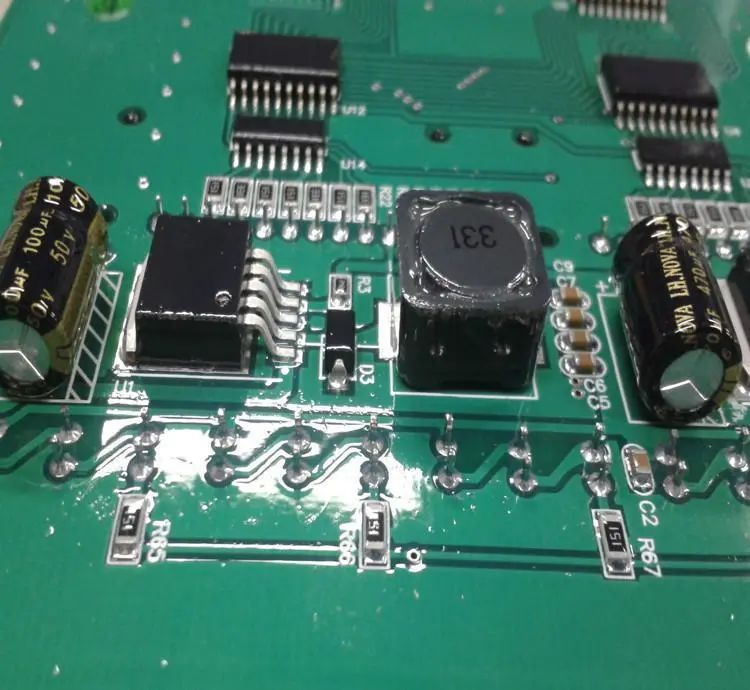

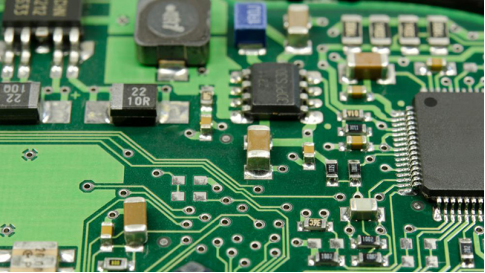

3. Foil na Stencil

Zaɓin kayan samfuri na SMT stencil dole ne suyi la'akari da dalilai irin su rigidity na kayan, juriya na lalata, ductility, da haɓakar haɓakar thermal, kamar yadda suke shafar rayuwar sabis na stencil kai tsaye (tsatsa, murdiya, da nakasar raga. ramuka). Kayan samfuri na yau da kullun sun haɗa da tin phosphor bronze, bakin karfe, da gami da nickel-chromium, tare da bakin karfe shine ya fi kowa. Ana amfani da waɗannan don ƙirƙirar buɗaɗɗen jan ƙarfe, bakin karfe, gami da nickel, da kayan polyester. Stencil gabaɗaya suna amfani da zanen bakin karfe mai inganci na 301/304 daga ƙasashen waje, waɗanda, tare da kyawawan kaddarorin injin su, suna haɓaka rayuwar sabis na stencil.

4. Manne

Manne da aka yi amfani da shi don haɗa firam da takardar ƙarfe yana taka muhimmiyar rawa a cikin stencil. An zaɓi shi musamman bisa yanayin amfani da abokin ciniki. Wannan manne yana kiyaye haɗin gwiwa mai ƙarfi kuma yana iya tsayayya da hadaddun tsarin tsaftacewa wanda ya ƙunshi nau'ikan tsabtace stencil iri-iri.

A cikin labarin na gaba, za mu tattauna abubuwan da ake buƙata na masana'anta don PCB SMT stencil.

Hausa

Hausa English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba