A yau za mu koyi game da wasu sassa na SMT PCB na musamman da kuma Abubuwan da ake buƙata don siffar da girman buƙatun buɗaɗɗen stencil na manne.

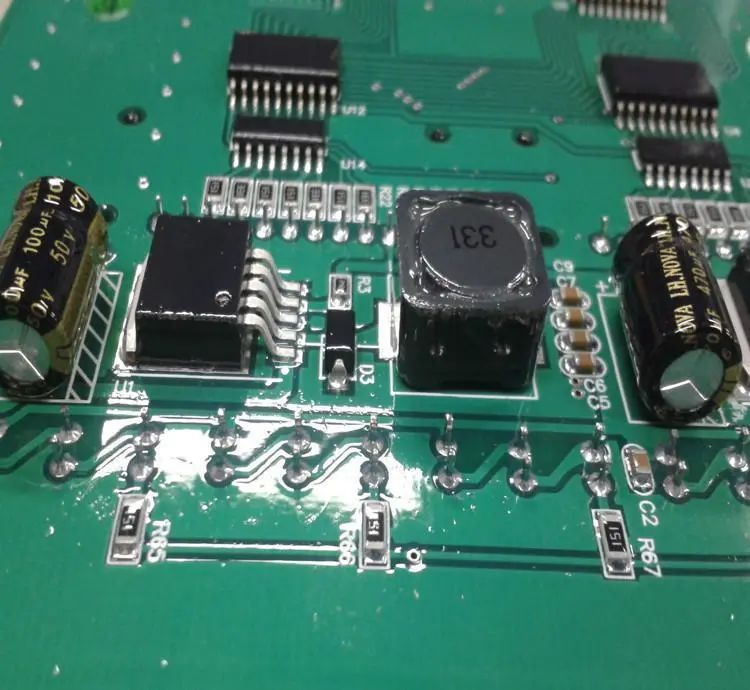

1. Ƙirar buɗe ido don wasu abubuwan SMT na musamman:

1) Abubuwan CHIP: Don abubuwan CHIP masu girma fiye da 0603, ana ɗaukar ingantattun matakai don hana samuwar ƙwallan solder.

2) SOT89 abubuwan da aka gyara: Saboda girman girman kushin da ƙananan tazarar kushin, ƙwallon solder da sauran matsalolin ingancin walda na iya faruwa cikin sauƙi.

3) SOT252 aka gyara: Tun da daya daga cikin gammaye na SOT252 ne quite manyan, shi ne yiwuwa ga solder bukukuwa kuma na iya haifar da tashin hankali a lokacin da tashin hankali. reflow soldering.

4) Abubuwan IC: A. Don daidaitaccen ƙirar kushin, ICs tare da PITCH na 0.65mm ko mafi girma, buɗaɗɗen nisa shine pad 90% , tare da tsawon da ya rage ba canzawa. B. Don daidaitaccen zane na pad, ICs tare da PITCH na ƙasa da 0.05mm suna da wuyar haɗawa saboda ƙananan PITCH. Tsawon budewar stencil ya kasance baya canzawa, faɗin buɗewar shine sau 0.5 PITCH, kuma faɗin buɗewar shine 0.25mm.

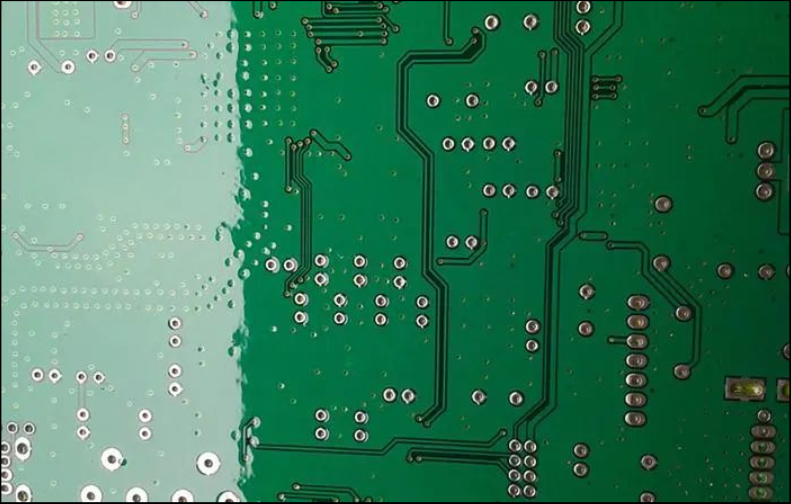

5) Wasu yanayi: Lokacin da pad ɗaya ya yi girma sosai, yawanci tare da gefe ɗaya mafi girma fiye da 4mm kuma ɗayan gefen ba kasa da 2.5mm ba, don hanawa. samuwar solder bukukuwa da canje-canje lalacewa ta hanyar tashin hankali, an bada shawarar yin amfani da grid line rabo hanya ga stencil budewa. Faɗin layin grid shine 0.5mm, kuma girman grid shine 2mm, wanda za'a iya raba shi daidai gwargwadon girman kushin.

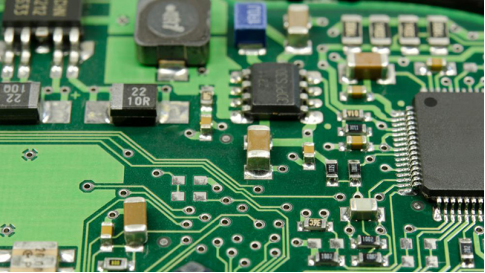

2. Abubuwan bukatu don siffa da girman buɗaɗɗen buƙatun akan tambarin bugu:

Don sauƙaƙan taruka na PCB ta amfani da tsarin manne, an fi son gluing. Abubuwan CHIP, MELF, da SOT ana manna su ta cikin stencil, yayin da ICs yakamata su yi Anan, kawai masu girma dabam da sifofi da aka ba da shawarar don CHIP, MELF, da SOT manne bugu an samar da su.

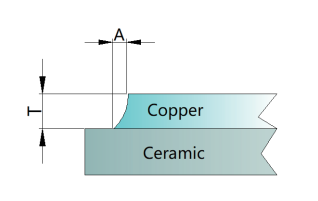

1) Diagonal na stencil dole ne ya sami ramuka na diagonal guda biyu, kuma ana amfani da maki FIDUCIAL MARK don buɗewa.

2) Budewar duk suna cikin siffa ta rectangular. Hanyoyin dubawa:

(1) Duba wuraren buɗe ido da gani don tabbatar da sun kasance a tsakiya kuma ragar ya kwanta.

(2) Duba ingantattun buɗaɗɗen stencil tare da PCB na zahiri.

(3) Yi amfani da ma'aunin ma'auni na bidiyo mai girman girma tare da ma'auni don duba tsayi da faɗin ramukan stencil, da kuma santsin ramin. ganuwar da farfajiyar takardar stencil.

(4) Ana tabbatar da kauri na takardar stencil ta hanyar auna kauri na manna solder bayan bugu, watau, tabbatar da sakamako.

Za mu koyi wasu ilimi game da PCB SMT stencil a labarin labarai na gaba.

Hausa

Hausa English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba