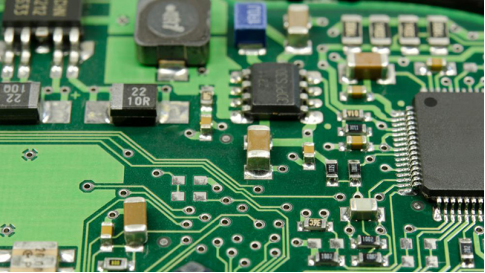

Bayan haka, muna ci gaba da nazarin ƙarfin lantarki na babban al'amari rabo na HDI.

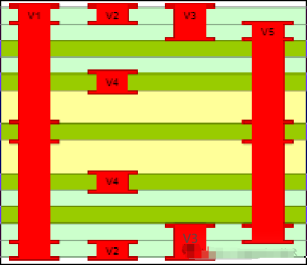

I. Bayanin samfur:

- kauri na allo: 2.6mm, mafi ƙarancin diamita ta rami: 0.25mm,

- Matsakaicin yanayin ramuka: 10.4: 1;

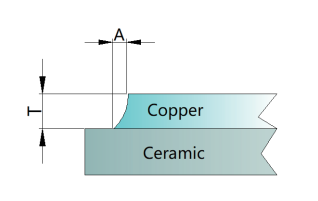

II. Vias Makafi:

- 1) Dielectric kauri: 70um (1080pp), rami diamita: 0.1mm

- 2) Dielectric kauri: 140um (2*1080pp), rami diamita: 0.2mm

III. Tsare-tsare Tsare-tsare:

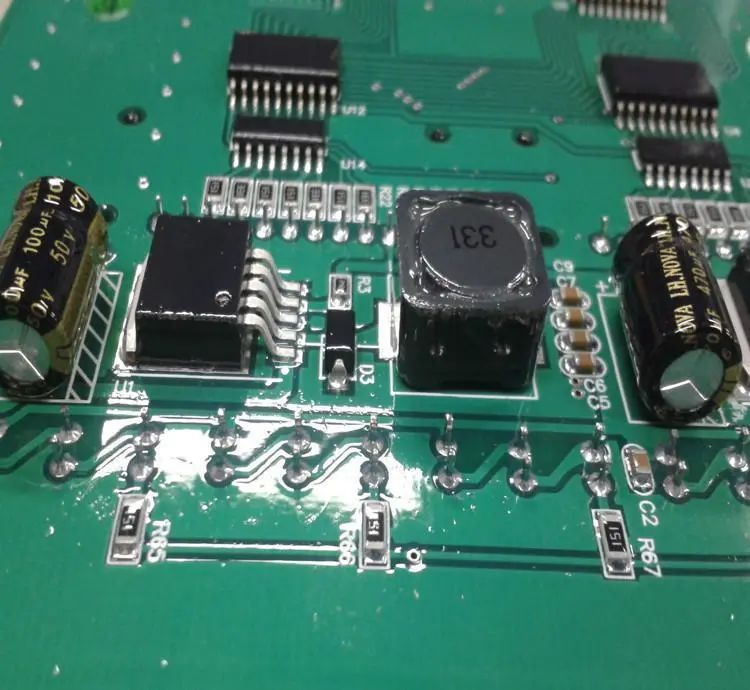

Tsari Na Farko: Wutar lantarki kai tsaye bayan sanyan jan karfe

- Amfani da babban acid low jan karfe bayani rabo, tare da H electroplating Additives; halin yanzu yawa 10ASF, lokacin lantarki 180min.

-- Sakamakon gwajin ci gaba na ƙarshe

Wannan rukunin samfuran yana da ƙarancin lahani na buɗewa 100% a cikin gwajin ci gaba na ƙarshe, tare da ƙimar lahani na buɗewa na 70% a makaho 0.2mm ta wurin (PP shine 1080*2).

Tsari na Biyu: Yin amfani da maganin electroplating na al'ada don faranti ta hanyar makafi kafin sanya ramuka:

1) Yin amfani da VCP don faranti na makafi, tare da rabon jan ƙarfe na al'ada na jan karfe da abubuwan haɗin H electroplating, sigogi na lantarki 15ASF, lokacin lantarki 30min {608201}

2) Yin amfani da layin gantry don yin kauri, tare da babban acid low tagulla rabo da H electroplating additives, electroplating sigogi 10ASF, electroplating lokaci 150min {60801}

-- Sakamakon gwajin ci gaba na ƙarshe

Wannan rukunin samfuran yana da ƙarancin 45% buɗewa a cikin gwajin ci gaba na ƙarshe, tare da ƙimar buɗewa ta 60% a makaho 0.2mm ta wurin (PP shine 1080*2) 4909101}

Idan aka kwatanta gwaje-gwajen guda biyu, babban abin da ya fi dacewa shi ne na'urar lantarki ta makafi, wanda kuma ya tabbatar da cewa babban acid low na jan karfe ba ya dace da makaho ta waya.

Saboda haka, a cikin Gwaji na Uku, an zaɓi wani ɗan ƙaramin acid mai cike da jan ƙarfe wanda zai fara fara fara faranta wa makaho ta hanyar, ya cika ƙasan makafi da ƙarfi kafin a sanya wutar lantarki ta makafi.

Tsari na uku: Yin amfani da maganin cikawa na lantarki don faranti ta hanyar makafi kafin sanya ramuka:

1) Yin amfani da bayani mai cike da lantarki don farantin makafi, tare da babban adadin jan ƙarfe low acid jan rabo da V electroplating additives, electroplating sigogi 8ASF@30min + 12ASF@30min {4901} }

2) Yin amfani da layin gantry don yin kauri, tare da babban acid low tagulla rabo da H electroplating additives, electroplating sigogi 10ASF, electroplating lokaci 150min {60801}

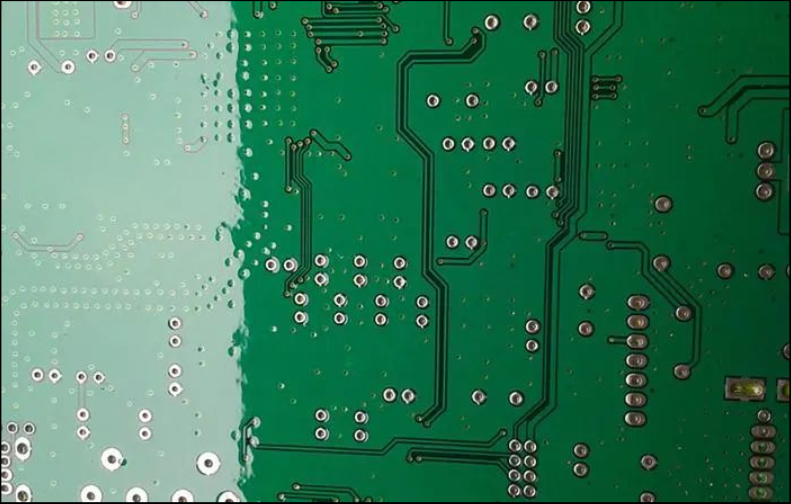

IV. Ƙirar Gwaji da Binciken Sakamako

Ta hanyar kwatancen gwaji, ma'auni daban-daban na tagulla na jan karfe da abubuwan da ake amfani da su na lantarki suna da tasirin electroplating daban-daban akan ramukan makafi. Don babban al'amari rabo HDI alluna tare da biyu ta hanyar da makafi ramukan, ana bukatar ma'auni ma'auni don dacewa da kauri tagulla a cikin ta ramukan da kaguwa ta kafar ramukan. Kaurin jan ƙarfe da aka sarrafa ta wannan hanya gabaɗaya ya fi kauri, kuma yana iya zama dole a yi amfani da goga na inji don biyan buƙatun sarrafa kayan etching na waje.

Batches na farko da na biyu na samfuran gwaji suna da lahani 100% da 45% a buɗe bi da bi a gwajin hutun jan ƙarfe na ƙarshe, musamman a makafi 0.2mm ta wurin (PP shine 1080*2) tare da Ƙididdigar ɓarna na da'ira na 70% da 60% bi da bi, yayin da rukuni na uku ba su da wannan lahani kuma sun wuce. 100%, yana nuna ingantaccen haɓakawa.

Wannan haɓakawa yana ba da ingantaccen bayani don tsarin lantarki na babban al'amari rabo HDI allon, amma sigogi har yanzu suna buƙatar ingantawa don cimma kauri mai kauri.

Duk abin da ke sama, shine takamaiman shirin gwaji da sakamako don nazarin ƙarfin lantarki na babban al'amari rabo HDI allo.

Hausa

Hausa English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba