-

Menene Rufaffen Kwamfuta a Masana'antar PCB (Sashe na 3)

-

Menene Rufaffen Kwamfuta a Masana'antar PCB (Sashe na 2)

-

Menene Rufaffen Kwamfuta a Masana'antar PCB (Sashe na 1)

-

Yadda ake Rusa Kayan Kayan Wutar Lantarki akan PCB (Sashe na 2)

-

Yadda ake Rusa Kayan Wutar Lantarki akan PCB (Sashe na 1)

-

Ma'anar Etch a cikin PCB Ceramic (Sashe na 2)

-

Menene Rufaffen Kwamfuta a Masana'antar PCB (Sashe na 3)

Bari mu ci gaba da koyo game da takamaiman buƙatun aiki. 1. Yanayin aiki 2.Kariyar mutum 3.Kayan aiki da sarrafa kwantena 4.Circuit board handling

-

Menene Rufaffen Kwamfuta a Masana'antar PCB (Sashe na 2)

A cikin labarin da ya gabata, mun bayyana takamaiman ayyuka da aikace-aikace na sutura masu dacewa. Na gaba, za mu tattauna ƙayyadaddun ƙayyadaddun tsari da buƙatun don amfani da shafi mai dacewa mataki-mataki.

-

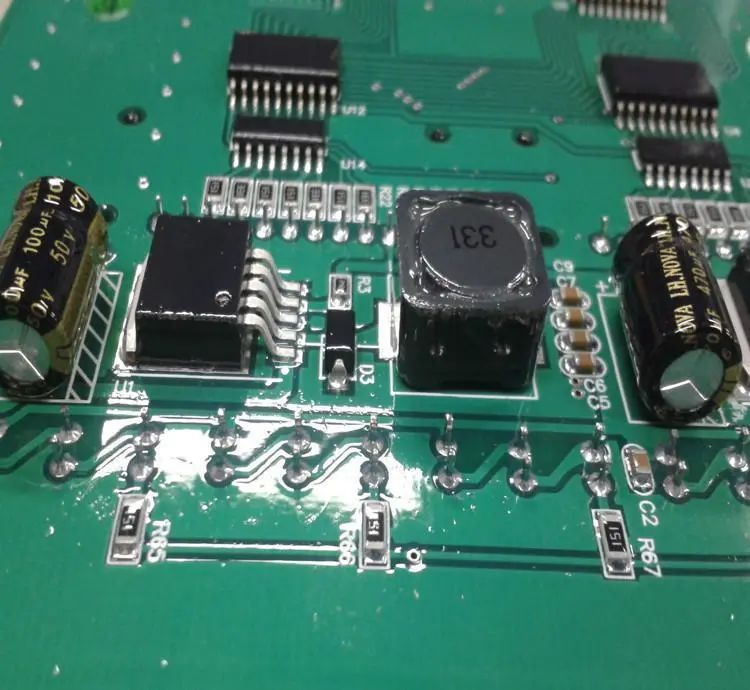

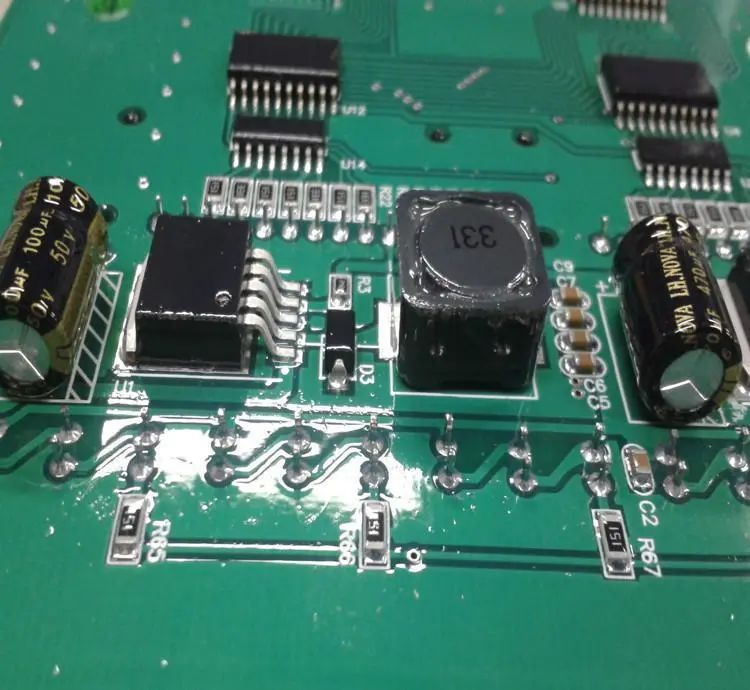

Menene Rufaffen Kwamfuta a Masana'antar PCB (Sashe na 1)

Sanannen abu ne cewa saman wasu samfuran PCB suna da santsi sosai, suna iya nuna haske, kuma galibi sun fi ɗorewa fiye da samfuran PCB na gaba ɗaya. To, ta yaya ake samun wannan? Amsar ita ce, masana'antun suna amfani da sutura ta musamman da ake kira conformal coating. A yau, bari mu kalli yadda suturar da ta dace ta sa PCB ta "haske da haske."

-

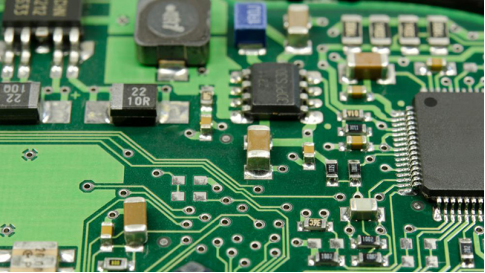

Yadda ake Rusa Kayan Kayan Wutar Lantarki akan PCB (Sashe na 2)

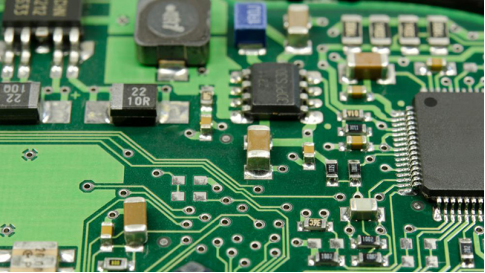

Bari mu ci gaba da koyon yadda ake cire abubuwa daga PCB mai yawan Layer. Cire abubuwan da aka gyara daga allunan da'ira bugu da yawa: Idan kayi amfani da hanyoyin da aka ambata a labarin da ya gabata (ban da hanyar injunan siyar da kwararar siyar), zai yi wahala cirewa kuma yana iya haifar da gazawar haɗin kai cikin sauƙi a tsakanin yadudduka.

-

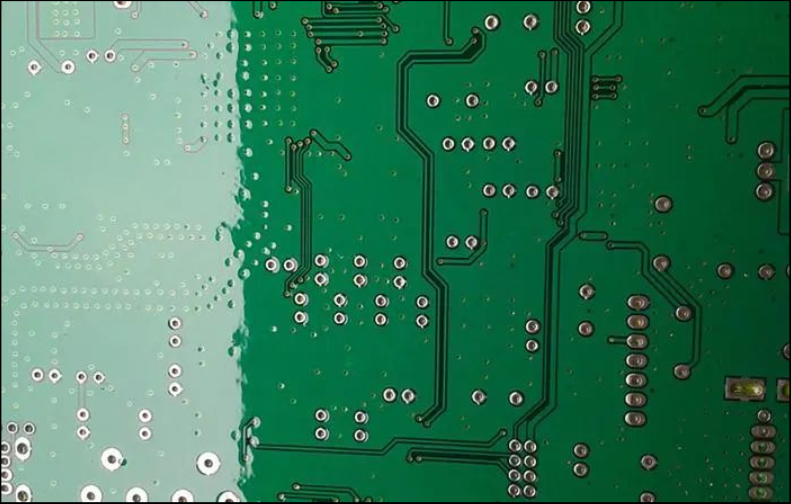

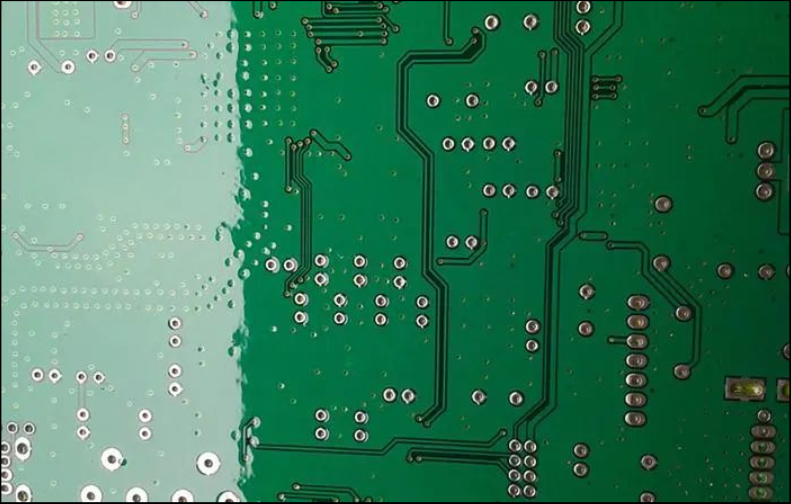

Yadda ake Rusa Kayan Wutar Lantarki akan PCB (Sashe na 1)

Bayan shigar da kayan aikin lantarki akan PCB, ƙila za ku buƙaci cire su daga PCB saboda dalilai kamar rashin daidaituwa ko lalacewa. Koyaya, ga yawancin mutane, cire kayan aikin lantarki ba abu ne mai sauƙi ba. A yau, bari mu koyi yadda ake cire kayan aikin lantarki.

-

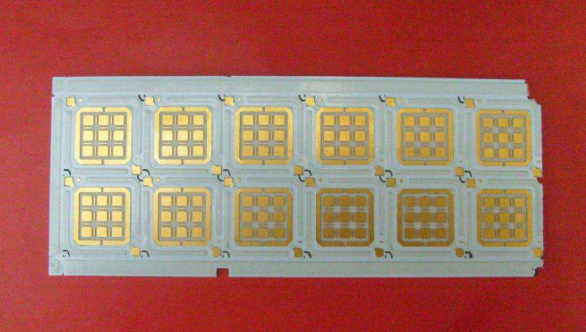

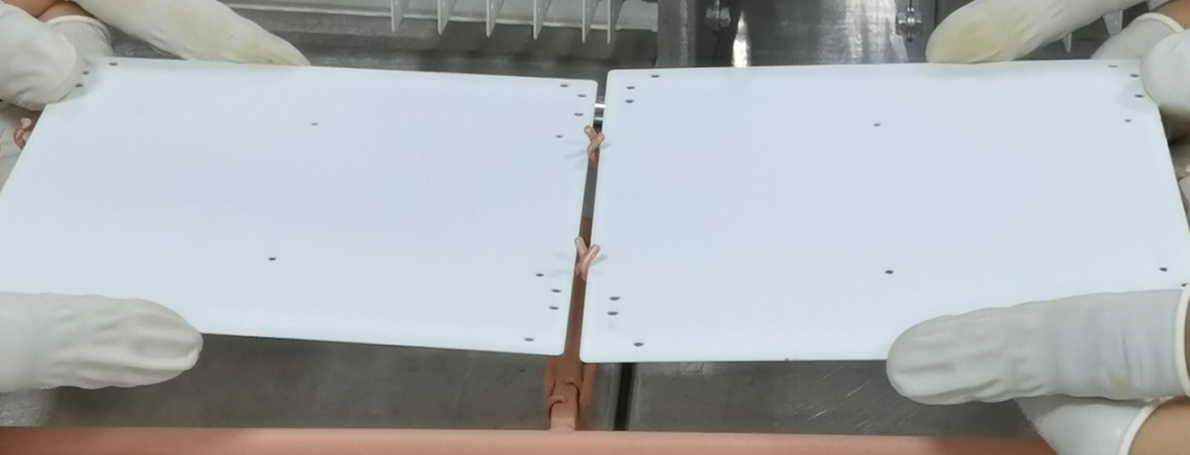

Ma'anar Etch a cikin PCB Ceramic (Sashe na 2)

Bari mu ci gaba da koyo game da abubuwan da ke shafar ma'aunin etching a cikin PCB yumbu da kuma yadda ake daidaita abubuwan etching don kera PCB yumbu mai girma.

-

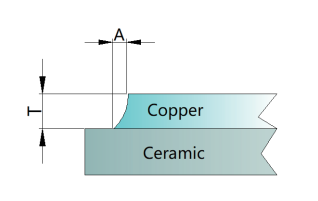

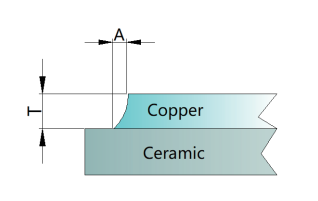

Alamar Etch a cikin PCB Ceramic (Sashe na 1)

Yau, bari mu fahimci abin da etching factor yake a cikin yumbu substrates. A cikin PCB yumbu, akwai nau'in PCB da ake kira DBC ceramic PCB, wanda ke nufin abubuwan yumbura na yumbura kai tsaye.

-

Aluminum Oxide a cikin PCB Ceramic (Sashe na 3)

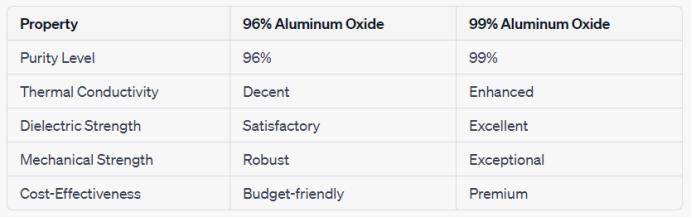

A yau, muna ci gaba da tattauna halaye na aikin 99% aluminum oxide. Idan aka kwatanta da 96% aluminum oxide, 99% aluminum oxide abu ne mai inganci tare da tsabta mai tsabta na aluminum oxide da ƙananan ƙarancin sinadarai. Ana amfani da shi musamman a cikin PCB yumbu wanda ke buƙatar ingantacciyar inji, lantarki, aikin zafi, ko juriya na lalata don jure matsanancin yanayin aiki.

-

Aluminum Oxide a cikin PCB Ceramic (Sashe na 2)

Bari mu ci gaba da koyon bambanci tsakanin 99% aluminum oxide da 96% aluminum oxide. Za mu fara daga 96% aluminum oxide......

-

Aluminum Oxide a cikin PCB Ceramic (Sashe na 1)

A cikin ƙirar PCB na lantarki mai inganci, zaɓin kayan da ya dace yana da mahimmanci. Daga cikin zaɓuɓɓukan da ake da su daban-daban, aluminum oxide (Al2O3) ya fito waje a matsayin kyakkyawan zaɓi don PCB yumbu saboda fitattun kaddarorin thermoelectric. Duk da haka, ba duk abubuwan da ke cikin aluminum oxide ba ne aka halicce su daidai. A cikin wannan da kuma labaran labarai da yawa masu zuwa, za mu shiga cikin bambance-bambancen bambance-bambance tsakanin kayan bambance-bambancen guda biyu: 96% aluminum oxide da 99% aluminum oxide. Za mu bincika keɓancewa da fa'idodin kayan biyu daban-daban.

Hausa

Hausa English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba