-

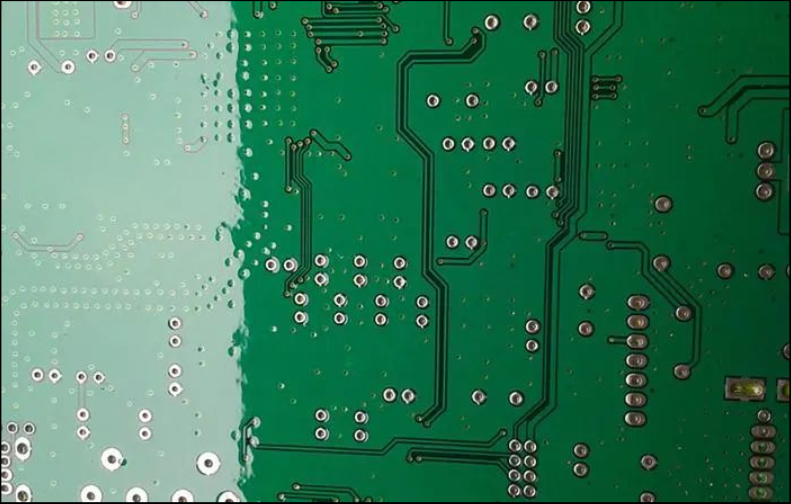

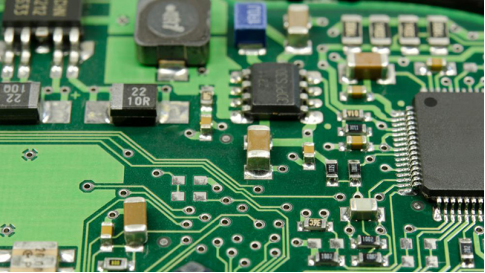

Menene Rufaffen Kwamfuta a Masana'antar PCB (Sashe na 3)

-

Menene Rufaffen Kwamfuta a Masana'antar PCB (Sashe na 2)

-

Menene Rufaffen Kwamfuta a Masana'antar PCB (Sashe na 1)

-

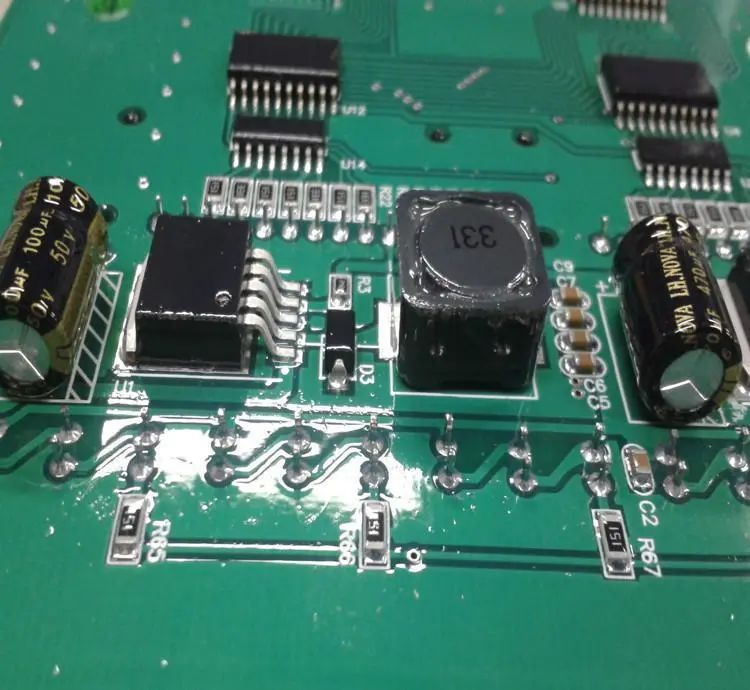

Yadda ake Rusa Kayan Kayan Wutar Lantarki akan PCB (Sashe na 2)

-

Yadda ake Rusa Kayan Wutar Lantarki akan PCB (Sashe na 1)

-

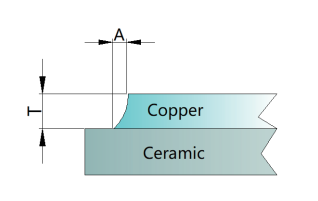

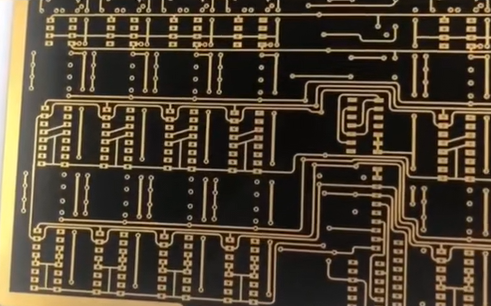

Ma'anar Etch a cikin PCB Ceramic (Sashe na 2)

-

Buƙatar Maskin Solder PCB

Fim ɗin juriya na solder dole ne ya sami ingantaccen tsarin fim don tabbatar da cewa ana iya rufe shi iri ɗaya akan wayar PCB da kushin don samar da ingantaccen kariya.

-

Menene Sirrin Launi a Mashin Solder PCB? (Kashi na 3.)

Shin PCB solder abin rufe fuska yana da wani tasiri akan PCB?

-

Bambancin Tsakanin Plating Zinariya da Tsarin Zinare na Immersion

Zinare na nutsewa yana amfani da hanyar saka sinadarai, ta hanyar hanyar mayar da sinadari don samar da wani Layer na plating, gabaɗaya mai kauri, hanya ce ta sanya shinge na nickel na gwal na sinadari, zai iya cimma wani kauri na zinariya.

-

Amfanin PCBs tare da Immersion Gold

翻译错误

-

Ka'idodin Tsarin Zinare na Immersion

Dukanmu mun san cewa, domin samun PCB mai kyau conductivity, da jan karfe a kan PCB ne yafi electrolytic jan karfe tsare, da kuma jan karfe solder gidajen abinci a cikin iska daukan hotuna lokaci ya yi tsayi da yawa sauki a oxidised,

-

Bincike akan Electroplating don PCBs HDI tare da Babban Halayen Ratio (Sashe na 2)

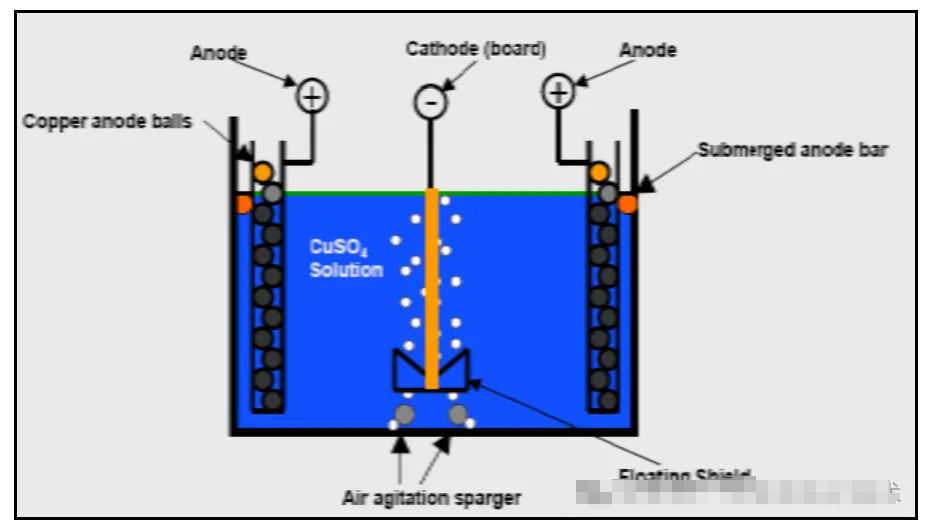

Na gaba, za mu ci gaba da nazarin ƙarfin lantarki na babban al'amari rabo HDI allon.

-

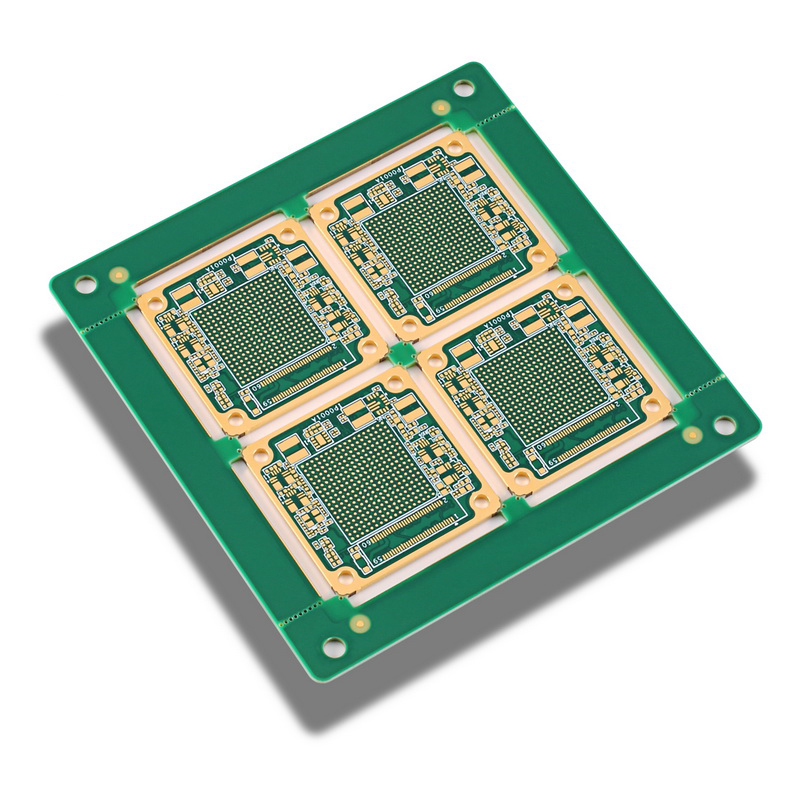

Bincike akan Electroplating don PCBs HDI tare da Babban Halayen Ratio (Sashe na 1)

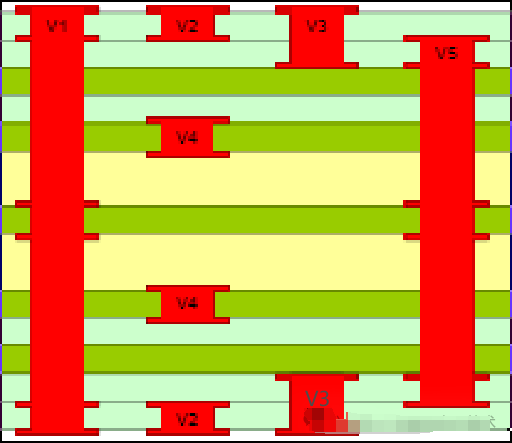

Kamar yadda muka sani cewa, Tare da haɓakar haɓakar haɓakar sadarwa da samfuran lantarki, ƙirar allon da'irar da aka buga azaman abubuwan jigilar jigilar kayayyaki shima yana motsawa zuwa matakan girma da yawa. Manyan jirage masu yawa na baya ko uwayen uwa tare da ƙarin yadudduka, kauri mai kauri, ƙananan ramuka, da wayoyi masu yawa za su sami ƙarin buƙatu a cikin mahallin ci gaba da haɓaka fasahar bayanai, wanda ba makawa zai kawo babban ƙalubale ga hanyoyin sarrafawa masu alaƙa da PCB. .

-

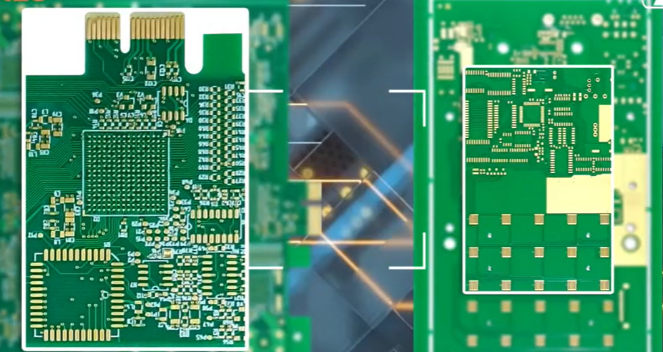

Tsarin PCB Wayar Hannu

PCB ta wayar hannu ɗaya ce daga cikin mahimman abubuwan da ke cikin wayar hannu, alhakin iko da watsa sigina gami da haɗi da sadarwa tsakanin nau'ikan nau'ikan daban-daban.

-

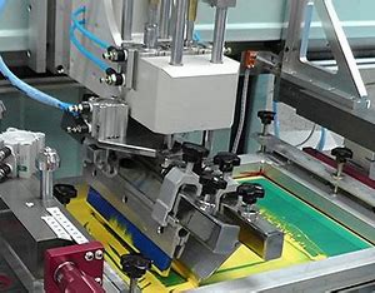

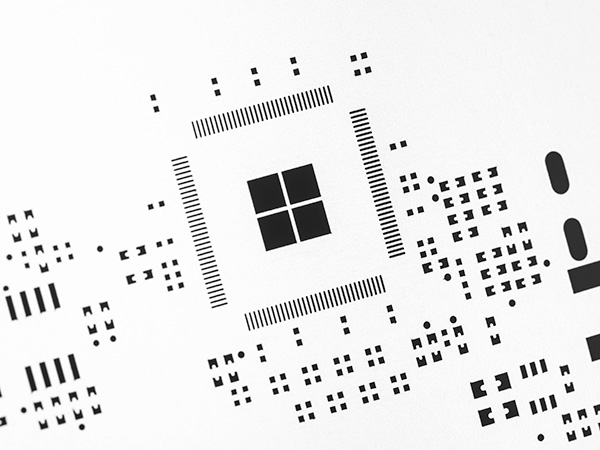

Menene PCB SMT Stencil (Sashe na 12)

A yau za mu ci gaba da koyo game da hanyar na biyu na kera PCB SMT stencil: Laser Cutting. Yanke Laser a halin yanzu shine mafi shaharar hanya don kera stencil na SMT. A cikin SMT karba-da-wuri sarrafa masana'antu, fiye da 95% na masana'antun, ciki har da mu, amfani da Laser yankan ga stencil samar.

-

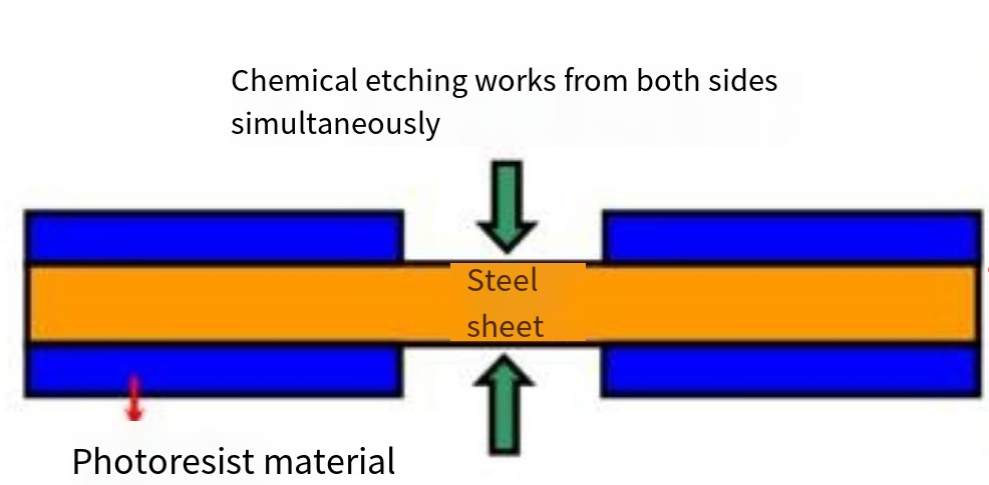

Menene PCB SMT Stencil (Sashe na 11)

A yau, za mu ci gaba da bincika hanyoyin uku na kera PCB SMT stencil: Chemical Etching (Chemical Etching Stencil), Laser Cutting (Laser Cutting Stencil), da Electroforming (Electroformed Stencil). Bari mu fara samar da sinadaran etching.

Hausa

Hausa English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba